Clampless Filter Bag

How does the product work ?

The Clampless filter bag is a dust bag most commonly used in industrial extractor systems. The Clampless Bag comes in a variety of lengths and the metal ring in the cuff comes in different sizes to fit a variety of cell plate diameters. As a standard we make the bag with a separate cuff.

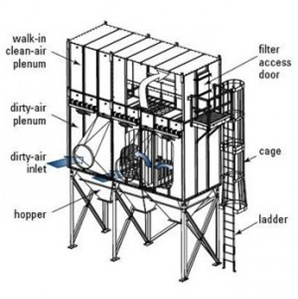

The units to which these bags fit operate by taking in dirty air through an inlet and as the air rises through the unit the dust forms a cake on the outside of the bag. The bag will then be cleaned via pulse jet cleaning this is when a blast of air inside the bag dislodges the ‘cake’ of dust. The dust then collects in a hopper and can be removed from the bottom of the unit.

The bag is fitted above in the walk-in clean air plenum so engineers avoid having to enter the area where dust is collected. This also means that engineers are fitting the bags at the level of there feet which can make fitting more difficult.

Below are some of the most common industries that these bags are used in;

- Air Pollution Control

- Pharmaceutical’s

- Manufacturing of Tobacco.

- Food Production.

- Production of Concrete.

How does the product fit?

The bag is first fitted onto small flange in the cell plate; the cage goes in after the bag and has a flat edge around it to catch on the flange. A seal is formed from a spigot/venturi twisting into the cell plate holding everything in place. The bag should be tight to the cage as any bagginess can reduce the effectiveness of cleaning. It is important that the bag has no crease as creases on the cage can lead to leakage in the bag. The Bag should be the length of the cage with no excess as excess can lead to a lot of movement at the bottom of the cage this can reduce the overall effectiveness of the pulse jet cleaning as energy is being absorbed. It also means that the bag will move more and therefore will wear much faster. The bag should be tight to the cage so there is a small pulse, which removes dust from the bag. In some case the fitters can put a sealing ring in the spigot to aid the seal.